Channel steel, also known as channel sections or simply "channel," is a type of structural steel with a C-shaped cross-section. It's commonly used in construction and manufacturing due to its strength and versatility. Here’s a detailed overview:

Chemical Composition

The chemical composition of channel steel can vary depending on the specific grade and standards followed. However, most structural steel channels are made from mild steel or carbon steel, which typically contains:

| Element | Composition Range | Effect on Properties |

|---|---|---|

| Carbon (C) | 0.12% to 0.30% | Increases strength and hardness |

| Manganese (Mn) | 0.60% to 0.90% | Improves strength and toughness |

| Silicon (Si) | 0.15% to 0.40% | Improves strength and elasticity |

| Phosphorus (P) | ≤ 0.04% | Increases strength but reduces ductility |

| Sulfur (S) | ≤ 0.05% | Can cause brittleness |

| Chromium (Cr) | 0.30% to 1.00% max | Improves hardness and corrosion resistance |

| Nickel (Ni) | 0.30% to 0.60% max | Improves toughness and corrosion resistance |

| Copper (Cu) | 0.20% to 0.50% max | Improves corrosion resistance |

Standard Sizes

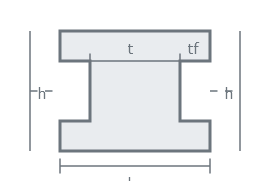

Channel steel sizes vary widely depending on the design requirements and regional standards. The dimensions are usually specified by the height of the channel, the width of the flange, and the thickness of the web and flange.

Common Dimensions

Height (h)50 mm to 300 mm (or more)

Width of Flange (b)30 mm to 200 mm (or more)

Web Thickness (t)4 mm to 12 mm (or more)

Flange Thickness (tf)5 mm to 15 mm (or more)

Channel Steel Profile

C-shaped cross-section with key dimensions

Applications & Standards

Common Applications

Building frames and structures

Bridge construction

Vehicle chassis and frames

Industrial equipment supports

Support structures and bracing

Manufacturing Standards

ASTMASTM A36 (USA)

ENEN 10025 (Europe)

JISJIS G3101 (Japan)

GB/TGB/T 706 (China)

ISIS 2062 (India)